Description

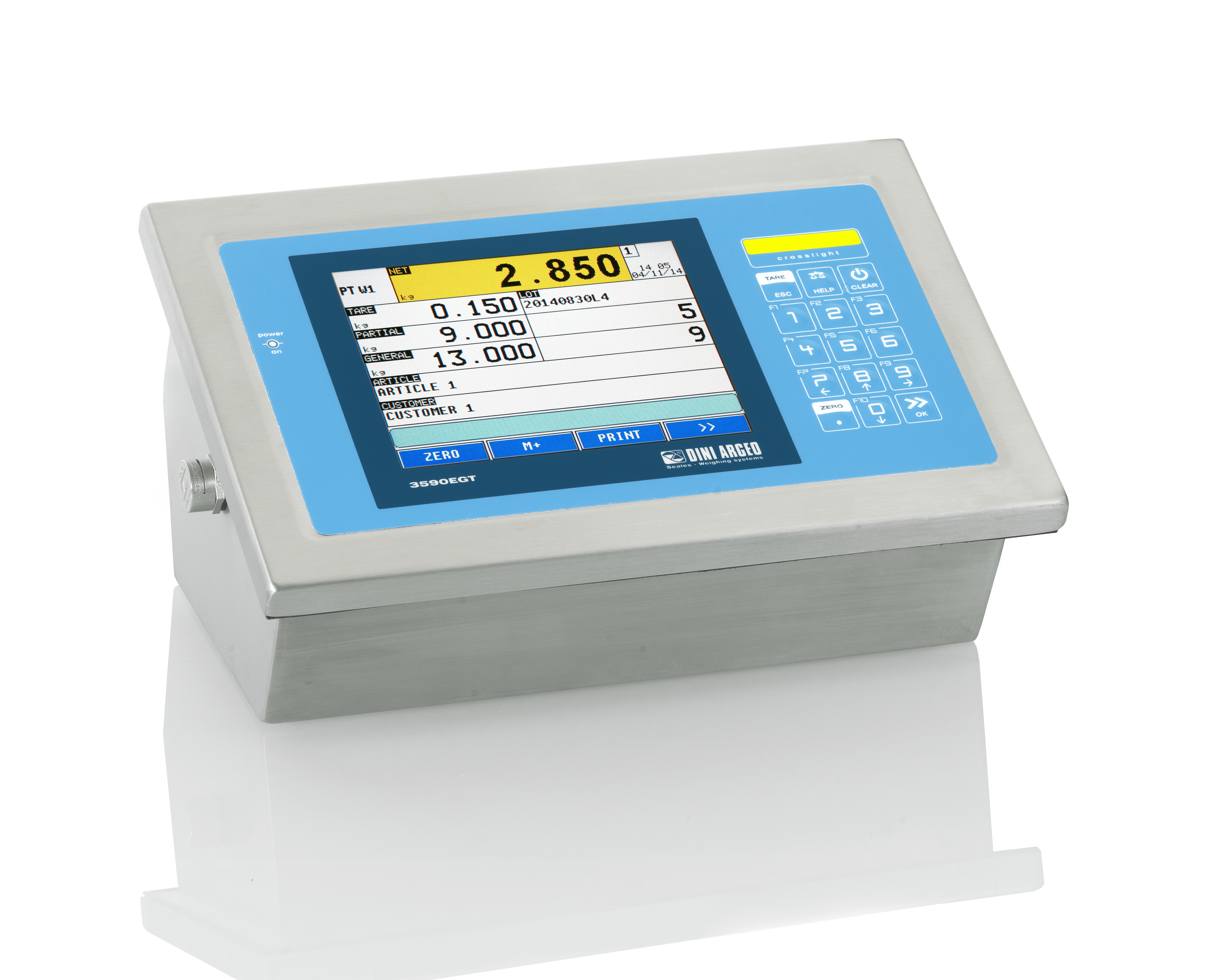

3590EGT “GRAPHIC TOUCH”: 3590EGTCXT01BC – Touch Screen weight indicator for industrial applications + 2 IN, 4 OUT, RS485

Digital weight indicator with a big touch screen display, suitable for advanced industrial applications. It allows the visualisation of all the weighing data and the customisation of the screens, simplifying the user operations. Fitted with 3 serial ports, transmission protocols for data communication, completely configurable printouts, integrated alibi memory, and port for connection to barcode/badge reader. CE-M approvable (OIML R-76 / EN 45501, OIML R-51 – OIML R-61 – MID for dynamic check weigher AWI).