Description

Revet Recycling srl is a manufacturing company that manages the recycling of mixed plastics through a profile production plant and granule production plant.

Customer need

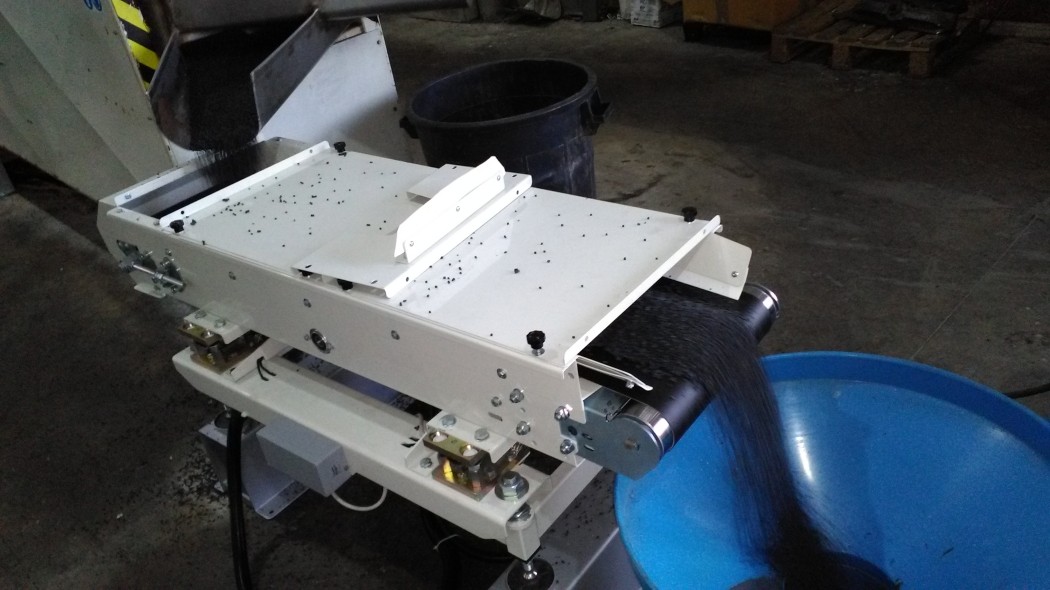

To equip a Gamma Meccanica recycling line consisting of a grinder, extruder, and granulator, Revet Recycling was looking for a system able to continuously monitor the production of granules at the extruder output:

- Flow rate capacity up to 3500 kg/h

- Continuous totalization accuracy from ±0.5% to 1.5%, according to flow rate and product type.